Curling is the most common anti-fatigue mat safety hazard. In fact, we surveyed 100 safety and production leaders, and curling was the No. 1 complaint they receive from employees.

Curling is a clear trip hazard, slows productivity, and forces you to buy new mats more often than you should. So, how can you stop your anti-fatigue mats from curling?

Here are 5 ways to prevent your anti-fatigue mats from curling.

1. Confirm you have the right materials.

The durability of your anti-fatigue mats is the most important factor in preventing curling. Here’s a look at three of the most popular anti-fatigue mat materials and their durability.

- PVC foam

- PVC/nitrile

- 100% nitrile

PVC foam is the most common anti-fatigue mat material. PVC/nitrile blends aren't far behind. While versatile and inexpensive, PVC is not impervious to liquids. In dry settings, mats with a PVC component will hold up for 1-2 years. In heavy industrial settings with oil, grease and chemicals, PVC allows these products to seep into the mats – causing them to buckle, crack and bloat. In turn, this lifts the edges of your mats off the ground.

100% nitrile is impervious to liquids and chemicals. It is physically incapable of absorbing liquids. Look for anti-fatigue mats made from 100% nitrile if you have a wet/oily environment; at the very least, make sure your mats have a warranty that protects against bloating and curling from liquids and particles.

This windows and doors manufacturer replaced curling and eroding PVC tiles with a 100% nitrile custom 100-1 Series mat. Unlike PVC and PVC/nitrile blends, 100% nitrile will not absorb liquids, flatten, or curl.

2. Look closely at the design of your mats.

If the material of your anti-fatigue mats is No. 1 in importance, design is 1A. They work hand in hand. Even the best materials poorly designed will lead to curling.

For example, the most common diamond-plate mat design is the "waterfall" approach. With this design, the anti-fatigue pad, often made from PVC, is smaller than the surface of the mat. In heavy industrial settings, the pad buckles and shrinks when met with chemicals. Because of the design, as the PVC pad shrinks it lifts the edges of your mats off the floor.

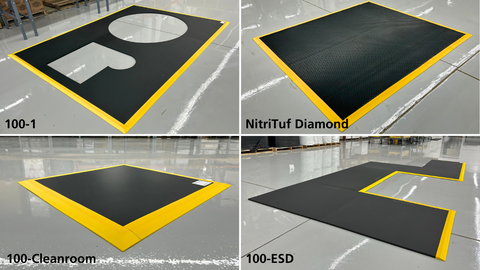

Left: Waterfall design and buckled PVC pad led to curling. Right: AcroMat NitriTuf Diamond Series cut-and-bonded at the edges to eliminate curling risks.

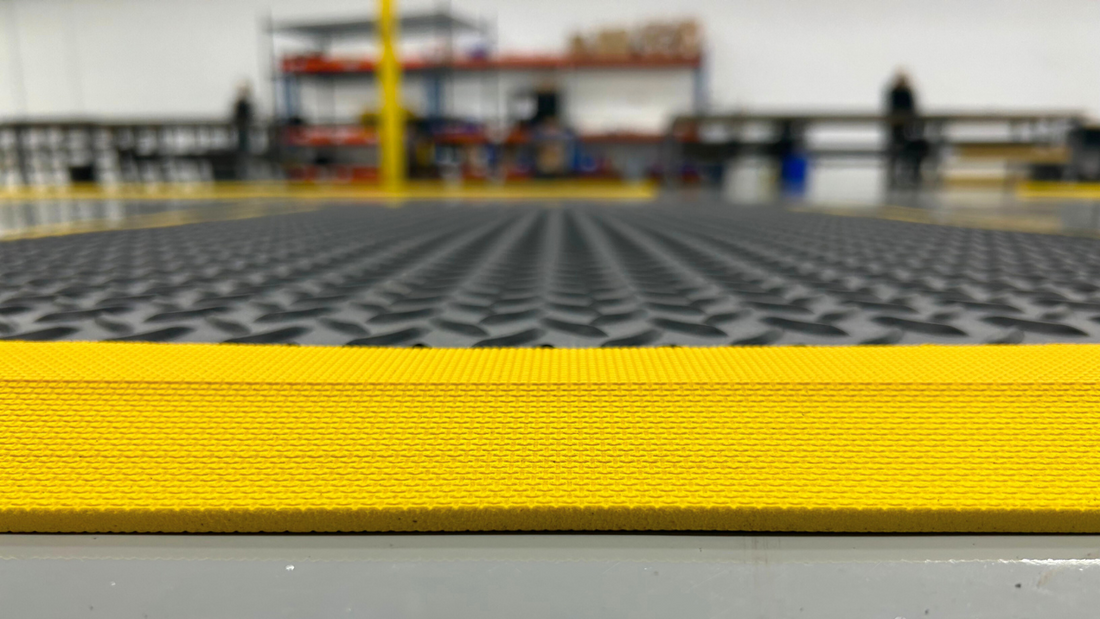

To prevent this issue, we use an exclusive cut-and-bond design at AcroMat combined with a higher quality of material to ensure durability. The anti-fatigue pad and diamond surface extend collectively to the edge of the mat – no overhang like the waterfall design. The 100% nitrile borders are then bonded to the mat. This design creates a natural and intentional transition to the floor, allowing us to guarantee our mats will never curl.

In addition to the NitriTuf Diamond Series, the AcroMat 100-1 Series, 100-Cleanroom Series, and 100-ESD Series anti-fatigue mats are guaranteed not to curl.

3. Review the Warranty

Every anti-fatigue mat should have a warranty. The warranty should be clear and concise. Before your next investment, review the warranty to see if it protects against curling. Be weary of ambiguous language that allows suppliers to void your warranty at their discretion.

This is directly from a “lifetime” warranty from a global, highly renowned mat provider: “Installing the mat may void the warranty" and "The decision to void this warranty will be made at the sole discretion of [Company X].” I.e., the moment you unbox your new mat, they can cancel your warranty without notice.

Here’s the AcroMat 2-year warranty in full:

The AcroMat 2-year full replacement warranty guarantees:

- The edges of your mat will NOT curl.

- The mat will NOT flatten or lose its ergonomic cushion.

- The bonds along your mat will NOT come apart.

You should know exactly what you’re getting with every warranty, before you buy.

Left: PVC/nitrile blends after 2 years, showing erosion and curling from liquid absorption. Right: 100% nitrile 100-1 Series mat after 5 years in a 24/7 facility; fully intact, no curling or erosion.

4. Ask Questions. Then Ask Some More.

Your mat provider should be thrilled to receive questions about their ergo mats. They should want you to have the answers you need and excited to talk about their design and materials.

Before your next investment, get clarity into these 5 questions:

✅How does the durability of your *materials* actively prevent curling?

✅Can you show me how the *design* actively prevents curling?

✅Does your product *warranty* protect against curling?

✅Will the mats *absorb* liquids or chemicals over time?

✅Do you receive *complaints* about curling?

Simple questions. Should be straightforward answers.

AcroMat General Manager Russell Herbert on-site with Daikin Applied and Allegion, presenting on mat design, materials, and installation to reduce slip, trip, and fall hazards. Questions? We'll respond today.

5. Put a FREE sample mat to the test.

Similar to No. 4, mat providers should be thrilled to provide samples. Before any major investment, get a sample and put it to the test. Not for days, but for weeks or months. When did your most recent mat investment begin to curl? Test your sample mat for at least this long.

Waterproof test: Soak a sample in water for multiple days, weighing the mat before and after. Above is a 72-hour test we conducted to illustrate the waterproof capabilities of 100% nitrile. The mat weighed the same before and after being submerged, indicating zero absorption.

Why do people settle for curling?

Curling has become widely accepted. Why? There are hundreds of anti-fatigue options. Everyone promises THE BEST. You’re moving fast, you trust what’s being promoted on product pages, and you have other priorities. You pick one option, invest, and a few months later it curls. You’ve already spent weeks on the project, so what do you do? Either start from scratch or put up with the problem.

Too many facilities put up with the problem. The result:

- Trip hazards

- Health risks

- Productivity barriers

Anti-fatigue products are designed to accomplish two things:

- Provide ergonomic support

- Eliminate slip, trip, and fall hazards

Putting an end to curling is an immediate and critically important way to reduce slip, trip, and fall hazards – still the No. 1 cause of workplace injury in manufacturing. It starts with design and materials. From there, continued research and testing to make sure the claims hold true.

--

Put an AcroMat sample to the test: Request a FREE Sample Mat

Want to take download, print, or share this this article? Click here for the digital eBook version: 5 Ways to Prevent Your Anti-Fatigue Mats from Curling